As one of the core processes in metal fabrication, sheet metal stamping has become a vital technological pillar for industries such as electronic casings, automotive manufacturing, aerospace, and medical devices due to its high efficiency, superior quality, and precision.

This article will explore the fundamental knowledge of sheet metal stamping, beginning with its basic definition, followed by an in-depth analysis of its technical advantages. It will systematically outline common sheet metal stamping methods and conclude with examples of its application scenarios.

What is Sheet Metal Stamping?

Sheet metal stamping is a cold forming manufacturing process that uses specialized dies and stamping equipment to apply pressure to metal sheets. This induces plastic deformation or separation, producing parts with specific shapes and dimensions.

This process typically involves three core elements:

Raw Materials: Metal coils or sheets, such as steel, aluminum, copper, stainless steel, etc.

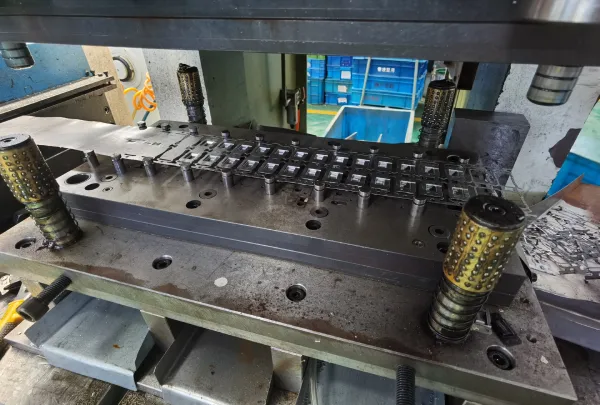

Sheet metal stamping dies: Typically consisting of a punch and a die, their cavities directly determine the final part’s shape. Once completed, dies enable high-speed, repetitive production of identical parts.

Stamping press: It provides the powerful, controlled pressure driving the dies to perform the stamping operation on the sheet metal.

Rapid Prototype Turnaround

Committed to exceeding expectations for quality and rapid turnaround, and meeting high-quality sheet metal parts.

On-Demand Sheet Metal

Whether it is rapid prototyping & large-volume manufacturing, we will implement it according to customer needs and standards.

Real Fabricators Price

Integrate product design, bending, stamping, cutting, surface treatment, etc. to provide a series of manufacturing solutions.

Advantages of Sheet Metal Stamping

Extremely high production efficiency and mass production capability: Once sheet metal stamping dies are fabricated, modern stamping production lines can produce hundreds or even thousands of parts per minute. This exceptional efficiency makes it the preferred choice for industries requiring large-scale manufacturing, such as automotive and home appliances.

High Cost-Effectiveness in Mass Production: While the initial manufacturing cost of sheet metal stamping dies is relatively high, the average cost per part becomes extremely low during mass production, achieving significant cost efficiency.

Consistency and Precision: Sheet metal stamping dies ensure every product is formed under identical conditions. This guarantees millions of parts exhibit perfectly consistent dimensions, shapes, and quality, delivering exceptional dimensional consistency and precision.

High Raw Material Utilization: By optimizing part layout on the sheet, raw material usage is maximized while minimizing scrap, effectively reducing material costs.

Superior Mechanical Properties and Strength-to-Weight Ratio: During sheet metal stamping, metal undergoes cold working hardening, enhancing part strength and hardness. Additionally, sheet metal stamping can produce thin-walled parts with reinforcing ribs, achieving lightweight construction while maintaining structural integrity.

Capability to produce complex part geometries: From simple brackets to structurally intricate automotive body components, sheet metal stamping enables the single-step production of complex geometric structural parts.

Common Sheet Metal Stamping Methods

Progressive Die Stamping

Working Principle: A set of sheet metal stamping dies incorporates multiple distinct stations, each sequentially performing different processing steps. As metal coil material is fed into the die, each stamping cycle advances the material by a fixed pitch. At each station, a different operation is completed—such as punching, bending, or drawing—until the final station separates the formed part from the strip.

Core Features and Advantages

High Efficiency: Extremely fast production speeds, capable of producing hundreds of parts per minute, making it ideal for ultra-high-volume orders.

Fully Automated: The entire process can be fully automated, from feeding and stamping to finished part collection.

Consistency: Exceptional part precision and uniformity due to sequential processing within a single sheet metal stamping die set.

Cost-Effectiveness: While sheet metal stamping dies require significant upfront investment, the cost per part is extremely low.

Typical Applications

Deep Drawing Stamping

Deep drawing stamping is a specialized forming technique used to manufacture hollow parts with significant depth.

Working Principle: A flat metal blank (referred to as a sheet) is positioned on the die cavity, where a holding ring applies pressure to prevent wrinkling. Subsequently, the punch moves downward, forcing the blank into the cavity of the die. This induces plastic deformation, forming cup-shaped, box-shaped, or other complex hollow structures. Depending on the required depth, a single part may necessitate multiple drawing operations to achieve completion.

Core Features and Advantages

Deep cavity production: Capable of manufacturing parts with high depth-to-width ratios that are difficult to achieve using other sheet metal stamping methods.

Seamless Construction: Produces sheet metal stamping products with seamless, monolithic structures that offer excellent strength and sealing integrity.

Uniform Material Distribution: Ensures consistent wall thickness through precise process control.

Typical Applications

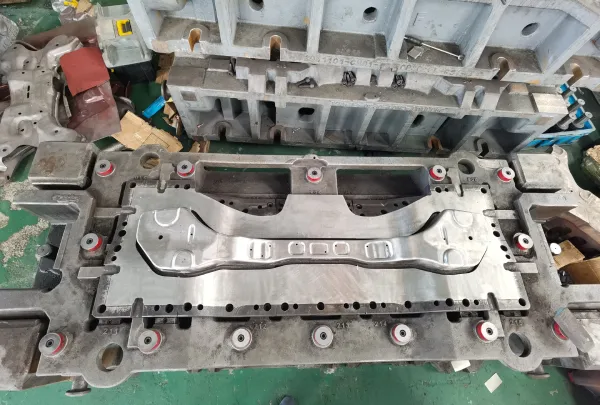

Compound Die Stamping

Working Principle: Compound dies integrate multiple processes (most commonly blanking and punching) into a single station. During a single downward stroke of the press ram, the die operates simultaneously to complete both blanking and punching, directly producing a complete flat plate-shaped part.

Core Features and Advantages

High Precision: Since blanking and punching occur during the same stamping cycle at identical positions, the part’s internal and external geometries achieve exceptional positional accuracy.

High Production Efficiency: A single sheet metal stamping stroke produces a finished part, significantly boosting productivity.

Ideal for Complex Flat Parts: Exceptionally suited for flat-plate components requiring high positional precision.

Typical Applications:

No design files? Let Supro MFG do it for you.

We often come across clients who have no professional design drawings and documentation, only a creative idea, which leads to the project being at a standstill.

If you are in this situation, then contact our team of experts.

Supro MFG, as an industry-leading custom metal fabricator, has an ever-experienced team of engineers who utilize their extensive fabrication experience and technical expertise to build your idea into a real product and create design files such as STEP/STP/SLDPRT/DXF/PDF/PRT/DWG/AI.

That’s what makes SUPRO MFG so great, and 2,000 corporate, entrepreneurial, artist, and other purchasers from around the world enjoy working with us and benefiting from our one-stop manufacturing services.

Common Applications of Sheet Metal Stamping

Automotive Industry: Doors, hoods, roofs, trunk lids, chassis longitudinal beams, cross members, suspension brackets, crash beams, etc.

Aerospace: Aircraft wing skins, frames, brackets, engine internal components, interior panels, etc.

Electronics and Communication Equipment: Metal mid-frames, enclosures, shielding covers, connectors, heat sinks for smartphones/laptops, etc.

Home Appliances: Refrigerator shells and door panels, washing machine shells and inner drums, microwave enclosures, oven cavities, etc.

Medical Devices: Surgical instruments, implant trays, equipment housings (e.g., MRI/CT scanners), hospital bed frames, precision sensor enclosures, etc.

Industrial Equipment: Generator components, agricultural machinery housings, oil storage tanks, solar panel mounts, etc.

Get An Instant Quote Now!

In summary, custom sheet metal stamping is a manufacturing technique involving multiple processes and operations. This simple and cost-effective method can produce a wide range of sheet metal parts. If you require sheet metal stamping services, contact us immediately—Supro is here to assist.

Supro is a sheet metal stamping manufacturer from China. With exceptional precision stamping technology and manufacturing capabilities, we produce standard/custom metal stampings and high-precision components. Our 2,500-square-meter precision stamping facility houses 80 sets of presses ranging from 6 tons to 1,000 tons.

We process materials from 0.005 inches to 5 inches thick and manufacture stamped parts up to 24 inches wide. Supro ships over 5 million metal stamped parts annually to global buyers, maintaining a 1,000-ton annual production capacity. If you require sheet metal stamping services, contact us immediately!