CNC cutting technology precisely controls machine tool movements through computer programs to cut materials into predefined complex geometric shapes. In modern manufacturing and creative design, It efficiently handles repetitive tasks in production processes, with manufacturing speeds far surpassing levels from years past, making it crucial for achieving high-precision, high-quality, and high-efficiency machining.

This article will provide a detailed analysis of CNC cutting, beginning with its fundamental definition, followed by an examination of its production process and suitable materials, and concluding with common applications. This will help you understand and appropriately utilize CNC cutting technology.

Definition of CNC Cutting

CNC cutting is an automated process where cutting equipment executes programs via digital instructions, comprising a numerical control system and mechanical framework. It offers exceptional production efficiency and cutting precision, supporting multi-axis coordination and complex pattern machining. Based on material differences, it can be categorized into CNC laser cutting (high-precision thin materials), CNC plasma cutting (medium-thick materials), and flame cutting (thick carbon steel). Operating costs and maintenance requirements vary by technology type.

Features of CNC Cutting

High Precision and Consistency: Once programmed, CNC machines achieve exceptional accuracy (typically ±0.025 mm or better), eliminating human errors caused by fatigue, skill variations, or inattention. This ensures consistent product quality and dimensional accuracy.

Automation: The entire CNC cutting process is automatically controlled by computer programs. From cutting paths and speeds to tool changes, no manual intervention is required. This not only reduces reliance on operator skill but also enhances production efficiency.

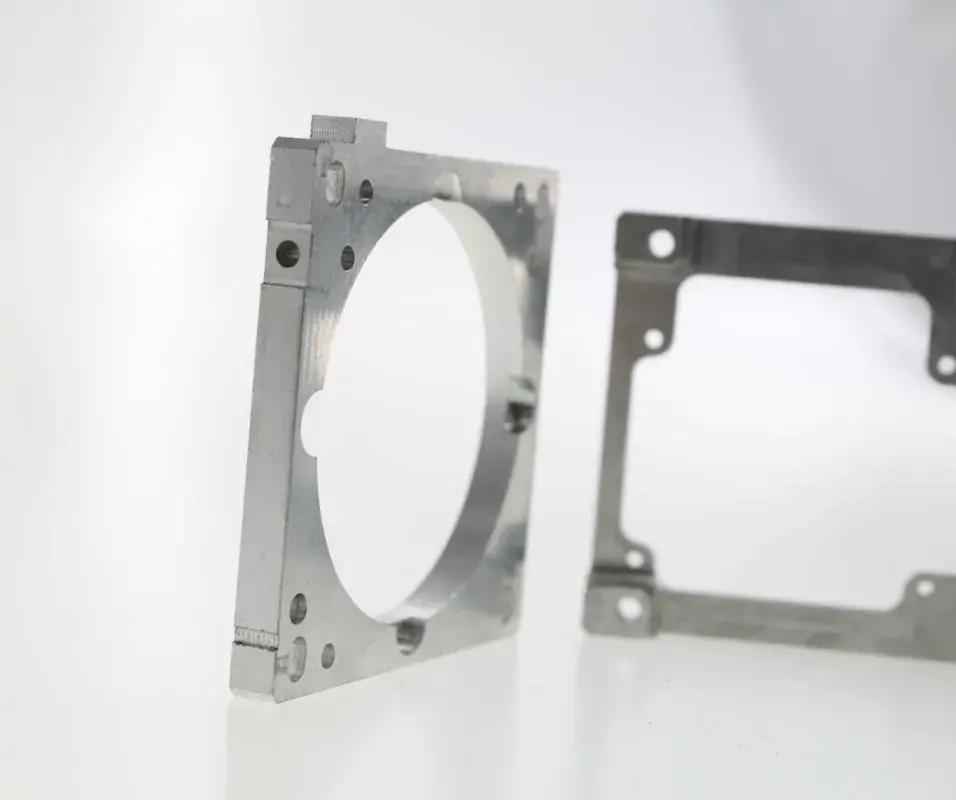

Complex Shape Machining: CNC cutting can execute intricate geometric shapes that are difficult to achieve with traditional manual methods. Whether it's two-dimensional contours, intricate three-dimensional surfaces, delicate engraved textures, or internal structures with strict geometric relationships, CNC cutting can materialize any design achievable through computer modeling.

High Efficiency and Flexibility: While initial programming requires time, once the program is set, CNC cutting operates at speeds far exceeding manual methods. It can produce multiple identical parts continuously around the clock. When switching to different parts, only the computer program needs adjustment or modification, along with tool and material changes—no complex physical modifications to the machine tool itself are required. This flexibility makes it ideal for batch production and customized manufacturing of diverse product lines.

Enhanced Safety: Since the machining process occurs automatically within enclosed or semi-enclosed protective covers, operators remain distant from cutting tools, high temperatures, and flying debris, significantly improving workplace safety.

Rapid Prototype Turnaround

Committed to exceeding expectations for quality and rapid turnaround, and meeting high-quality sheet metal parts.

On-Demand Sheet Metal

Whether it is rapid prototyping & large-volume manufacturing, we will implement it according to customer needs and standards.

Real Fabricators Price

Integrate product design, bending, stamping, cutting, surface treatment, etc. to provide a series of manufacturing solutions.

CNC Cutting Process

Phase One: Preliminary Preparation

CAD Design: Create 2D or 3D digital models of parts using computer-aided design software. Engineers or designers define all part dimensions, geometries, and details during this phase.

CAM Programming: Import the CAD model into computer-aided manufacturing software. Within the CAM software, the operator must:

- Select appropriate CNC cutting tools based on material and requirements.

- Plan the toolpath, determining cutting sequence, depth, and area.

- Input critical parameters such as cutting speed, feed rate, and spindle speed.

The CAM software automatically generates G-code that the CNC machine can interpret based on these settings.

Machine Setup: Transfer the generated program to the CNC machine controller. Simultaneously, the operator installs the appropriate CNC cutting tools on the machine, sets the machine coordinate origin to ensure precise tool starting position, and secures the raw material to the worktable.

Phase Two: Machining Execution

After the operator initiates the program, the CNC controller reads the G-code instructions.

The controller drives servo motors to precisely coordinate the cutting head's movement across multiple axes, executing cuts along the predefined path.

Cutting fluid or gas may be used to cool the tool and remove chips.

Throughout the CNC cutting process, the operator monitors the machine's operational status to ensure normal functioning without abnormal vibrations or noise.

Phase 3: Post-Processing

Part Removal and Cleaning: After CNC cutting completes, the machine stops. The operator removes the finished part from the worktable and cleans residual debris, coolant, etc., from the part.

Initial Inspection and Post-Processing: Key dimensions undergo preliminary inspection using measuring tools. Post-processing such as deburring, grinding, polishing, or surface treatment is performed as needed to achieve the final finished product.

No design files? Let Supro MFG do it for you.

We often come across clients who have no professional design drawings and documentation, only a creative idea, which leads to the project being at a standstill.

If you are in this situation, then contact our team of experts.

Supro MFG, as an industry-leading custom metal fabricator, has an ever-experienced team of engineers who utilize their extensive fabrication experience and technical expertise to build your idea into a real product and create design files such as STEP/STP/SLDPRT/DXF/PDF/PRT/DWG/AI.

That’s what makes SUPRO MFG so great, and 2,000 corporate, entrepreneurial, artist, and other purchasers from around the world enjoy working with us and benefiting from our one-stop manufacturing services.

Materials Suitable for CNC Cutting

CNC cutting technology offers high adaptability and flexibility, capable of processing various materials including metals and non-metals. Material selection directly depends on the end product's application requirements, performance specifications, and the CNC cutting method employed (such as milling, CNC laser cutting, CNC plasma cutting, or waterjet cutting).

Metal Materials

Metal materials represent the most common and extensively used category in CNC cutting.

Aluminum and Aluminum Alloys: Among the most popular CNC cutting materials, offering an excellent strength-to-weight ratio, ease of machining, corrosion resistance, and superior electrical conductivity. Widely used in aerospace, automotive, and consumer electronics enclosures.

Carbon Steel: Durable and cost-effective, used for manufacturing tools, fixtures, and structural components.

Stainless Steel: Offers superior corrosion resistance and strength, commonly used in medical devices, food processing equipment, and chemical processing.

Titanium and Titanium Alloys: Extremely high strength, lightweight, and excellent biocompatibility, but challenging to machine. Primarily used in aerospace, military, and medical implants.

Brass and Copper: Excellent electrical and thermal conductivity with corrosion resistance. Commonly used in electronic components, valves, fittings, and decorative items.

Plastics and Synthetic Materials

ABS: Tough, impact-resistant, and easy to post-process (e.g., painting). Frequently used for prototyping and electronic enclosures.

Polycarbonate (PC): Offers exceptional impact strength and transparency, used for safety eyewear, face shields, and automotive lens covers.

POM: Features high rigidity, low friction, and excellent dimensional stability, making it ideal for precision gears, bearings, and slides.

PEEK: A high-performance specialty plastic resistant to high temperatures and chemical corrosion, with mechanical properties approaching metals. Commonly used in aerospace and medical devices.

Acrylic (PMMA): Offers exceptional transparency and is easy to cut and polish, widely used in advertising signage, display stands, and lighting fixtures.

Other Materials

Wood: CNC-cut wood is commonly used in furniture manufacturing, artistic creations, and model making.

Composites: Such as carbon fiber-reinforced composites and fiberglass, which are lightweight yet extremely strong, frequently employed in high-performance sports equipment, automotive components, and aerospace parts.

Applications of CNC Cutting

CNC cutting finds extensive application, permeating nearly every corner of modern manufacturing and creative industries. Its high precision, efficiency, flexibility, and ability to handle complex geometries make it the preferred technology for prototyping and mass production. Key application areas include:

Prototype Development: During product R&D, CNC cutting rapidly and accurately transforms design drawings into functional prototypes.

Aerospace: Used to machine complex components demanding high strength-to-weight ratios, such as turbine blades, airframe structural parts, and cockpit instrument panels.

Automotive Industry: From core metal components like engine blocks and transmission gears to non-metallic parts including interior dashboards and lamp housings, CNC cutting technology is essential.

Electronics Industry: Used to produce precision enclosures for electronic devices (e.g., smartphones, laptops), heat sinks, and internal connectors and insulating components.

Medical Devices: CNC cutting manufactures surgical instruments, implants, diagnostic equipment housings, and intricate medical instrument parts, ensuring product reliability and safety.

Why choose Supro MFG's Custom metal enclosure Services

Provide the most cost-effective cost solution for manufacturing and assembling products, expanding product competitiveness.

a technical team specializing in custom shell manufacturing for more than 30 years.

Advanced Manufacturing Equipment: Industry-leading custom metal enclosure manufacturer with in-house sheet metal, die casting, precision machining workshops, and surface coating workshops.

ISO 9001-2015, PPAP III level, RoHS, NEMA, CE and other certified production standards.

24H*7 online English technical support: The professional English team responds quickly to users’ technical questions online at any time.

help users from product design, prototype, batch manufacturing, surface treatment, assembly and packaging, transportation and a series of value-added services.

With in-house mechanics and chemistry laboratories, it can quickly monitor manufacturing process quality control to ensure the delivery of high-quality products.

Accept to sign NDA documents to ensure that customers’ product information is protected.

Door-to-door delivery in customizable secure packaging after complying with the delivery details agreed with the customer.

Get An Instant Quote Now!

In summary, CNC cutting technology offers significant advantages including high efficiency, precision, and flexibility, making it an indispensable pillar of modern manufacturing.

If you require CNC cutting services, contact us immediately! Supro is a CNC fabrication manufacturer based in China, equipped with 80 3-axis, 4-axis, and 5-axis CNC machines. We offer over 120 types of metal and plastic materials, with all production processes completed in-house. We provide professional CNC cutting services and online technical support. Whether you require rapid prototyping or bulk production of metal/plastic parts, we deliver comprehensive manufacturing solutions!