Custom aluminum fabrication services

Supro MFG has focused on custom aluminum alloy parts for more than 20 years. There is no minimum order quantity limit, high-efficiency rapid prototyping, and a real Chinese manufacturer's quotation.

- On-time delivery

- Extensive experience

- Professional technical knowledge

- Rapid Prototyping

- Complete manufacturing capacity

- Real Manufacturer Factory Price

All information is safe and confidential

about aluminum fabrication services

Aluminum fabrication services is a low-cost solution for custom metal parts and prototypes.

Aluminum alloy has good processing properties, high strength and flexible surface treatment, making custom aluminum fabrication widely used in various industries.

The aluminum alloy material is a lightweight and non-magnetic metal material formed by mixing some metal elements based on pure aluminum. The density of the aluminum alloy is 2.63~2.85g/cm3, and it has high strength (σb is 110~650MPa), has special properties such as light weight, thermal conductivity, easy welding, corrosion resistance and chemical resistance, and can meet various harsh environments and functional requirements.

Contact our team of experts for more specialty aluminum alloy material options.

custom aluminum fabrication services

Supro MFG possesses extensive manufacturing experience and specialized technical expertise in custom aluminum fabrication, enabling the rapid implementation of various precision manufacturing processes or combinations thereof to achieve batch production and rapid prototyping of customized aluminum products.

aluminum laser cutting

aluminum sheet metal

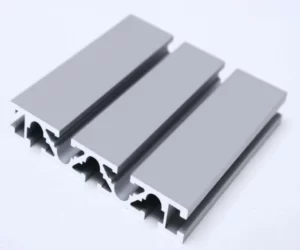

aluminum extrusion

aluminum welding

Surface treatment

aluminum bending

aluminum CNC machining

aluminum stamping

Why choose Supro MFG's aluminum fabrication Services

At Supro MFG, we offer one-stop custom aluminum fabrication services, helping you select the right aluminum materials for your projects and efficiently deliver the parts your customers need. We preserve the original properties of the aluminum alloy while meeting all quality requirements.

Certified to ISO9001 and TS16949, we refuse to cut corners. We accelerate custom aluminum alloy part manufacturing projects for all clients with cost-effective factory pricing and world-class quality standards.

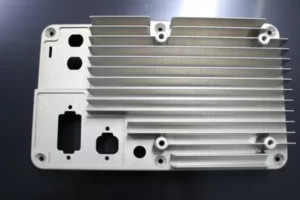

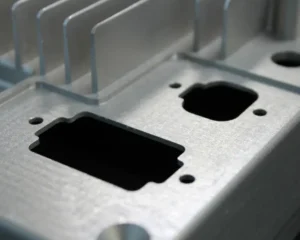

Whether you require precision-engineered aluminum alloy components, high-strength IP65 aluminum enclosures, standard aluminum extrusions, or uniquely designed custom aluminum prototypes, our knowledgeable and skilled team delivers expert technical guidance and comprehensive manufacturing solutions.

Supro MFG is committed to delivering exceptional standards, highly competitive pricing, and truly unmatched aluminum product options, while actively providing friendly, reliable, and professional on-demand manufacturing services.

Provide the most cost-effective cost solution for manufacturing and assembling products, expanding product competitiveness.

a technical team specializing in custom shell manufacturing for more than 30 years.

Advanced Manufacturing Equipment: Industry-leading custom metal enclosure manufacturer with in-house sheet metal, die casting, precision machining workshops, and surface coating workshops.

ISO 9001-2015, PPAP III level, RoHS, NEMA, CE and other certified production standards.

24H*7 online English technical support: The professional English team responds quickly to users’ technical questions online at any time.

help users from product design, prototype, batch manufacturing, surface treatment, assembly and packaging, transportation and a series of value-added services.

With in-house mechanics and chemistry laboratories, it can quickly monitor manufacturing process quality control to ensure the delivery of high-quality products.

Accept to sign NDA documents to ensure that customers’ product information is protected.

Door-to-door delivery in customizable secure packaging after complying with the delivery details agreed with the customer.

Strong ability to

custom aluminum fabrication services

Supro MFG has focused on customized aluminum fabrication parts and rapid prototypes for more than 20 years, providing the highest quality customized aluminum fabrication services and related industrial aluminum alloy profile capabilities.

With professional aluminum fabrication technology and rich manufacturing experience, we have received unanimous praise from global buyers and become the preferred supplier of customized aluminum fabrication parts.

- On time delivery

- Rich experiences

- Professional technical knowledge

- Advanced internal manufacturing equipment

- Complete manufacturing capability

- Real aluminum fabricator price

Custom aluminum alloy parts

material solutions

Custom aluminum fabrication parts involve the deep processing of various types of aluminum alloy raw materials. This not only meets the functional requirements and applications of the products but also significantly reduces material and processing costs, offering greater economic benefits.

1xxx: 1050, 1050A, 1060, 1100

2xxx: 2014 2017 2024

3xxx: 3003, 3004, 3005, 3105

5xxx: 5005, 5052, 5754, 5083

6xxx: 6061, 6082, 6063

7xxx: 7075

Formability and surface treatment are good, and its corrosion resistance is the best among aluminum alloys. The higher the purity, the lower the strength. Daily necessities, aluminum plates, lighting appliances, reflectors, decorations, chemical industry containers, heat sinks, melted wires, conductive materials.

Contains a large amount of Cu, poor corrosion resistance, but high strength, can be used as a structural material, forged products can also be used, aircraft, gears, oil, pressure components, wheel and axle.

Formability, weldability, and corrosion resistance are all good. General utensils, heat sinks, makeup boards, photocopier drums, and ship materials have excellent formability and good corrosion resistance. Aluminum cans, light bulbs, roof panels, colored aluminum panels

Good heat resistance and friction resistance, and low thermal expansion coefficient. Piston, cylinder head

Sulfuric acid anodizing treatment gives a natural gray color. Fusion wiring, building panels

5052 is the most representative alloy with medium strength. It has good corrosion resistance, weldability and formability, especially high fatigue strength and good seawater resistance. General sheet metal, ships, vehicles, construction, bottle caps, honeycomb panels, low-temperature vessels, pressure vessels.

6061 heat-treated corrosion-resistant alloy. T6 treatment can have a very high endurance value, but the strength of the welding interface is low, so it is used in screws, anchors, ships, vehicles, and land structures. 6N01 is a medium-strength extrusion alloy with a strength between 6061 and 6063. , Extrudability, stamping and hardenability are all good, can be used as large-scale thin-meat-shaped materials with complex shapes, good corrosion resistance and weldability. Vehicles, land structures, ships

6063 representative extrusion alloy, with lower strength than 6061, good extrudability, can be used as a profile with complex cross-section shape, good corrosion resistance and surface treatment, construction, highway guardrail, high fence, vehicle, Furniture, home appliances, decorations

7075 aluminum alloy has one of the highest strength alloys, but the corrosion resistance is not good, and the covering skin of 7072 can improve its corrosion resistance, but the cost is increased. Aircraft, ski poles 7050 7050 alloy with improved hardenability of 7075, good stress corrosion crack resistance, suitable for thick plates, forged aircraft, high-speed rotating bodies, 7N01 alloy for welding structure, high strength and the strength of the welding part can be placed at room temperature. After returning to the strength close to the base metal. The corrosion resistance is also very good. Vehicles, other land structures, aircraft

Aluminum fabrication material type

Aluminum alloys have good plasticity and easy processing properties and can create a rich variety of raw material types to adapt to the different custom aluminum fabricated needs of various industries.

Aluminium-alloy bars

Aluminium Alloy Pipe

Aluminium-alloy tube

Aluminium-alloy sheet

Aluminium embossed panels

Aluminium extruded profiles

performance and application industry

Customized aluminum alloy parts have the characteristics of low density, good mechanical properties, good processing properties, non-toxic, easy to recycle, electrical conductivity, heat transfer and corrosion resistance. They are used in the marine industry, chemical industry, aerospace, metal packaging, and transportation. Widely used in transportation and other fields.

- Good corrosion and chemical resistance

- Easy processing, high strength

- Light weight

- Low cost materials

- Excellent thermal and electrical conductivity

- Flexible surface treatment solutions

- Rich selection of performance alloys

performance

Basic description

Application industry

Light weight

The density of aluminum alloy is 2.702g/cm³, which is 1/3 of that of steel.

Suitable for aerospace parts manufacturing, automotive manufacturing, shipbuilding, engineering construction, heavy machinery, industrial parts, household appliances, medical supplies and sealed containers, etc.

High strength

By adding copper, zinc, magnesium, manganese, chromium and other elements to form aluminum alloy materials, the strength can replace ordinary steel materials. Moreover, after heat treatment, the hardness of aluminum alloy can exceed that of special steel.

Used in engineering construction, aerospace parts, hardware parts, key parts of enterprises and automobiles, fasteners, etc.

Easy machining

Excellent ductility makes aluminum alloy suitable for various cold forming manufacturing processes such as extrusion molding, stretch molding, and sheet metal bending.

Hollow structural parts, sealed containers, structural frames, and other precision parts with complex structures.

Custom surface treatment

Aluminum alloy can be suitable for all physical surface treatments, creating beautiful surface effects, and anodized through chemical treatments to enhance surface strength, wear resistance, and even custom colors.

Household items, decorative shells, signs, doors and windows, auto parts, aircraft shells, interior decoration materials, instrument shells, etc.

Thermal and electrical conductivity

Aluminum alloy is a very good thermal and conductive material, second only to copper alloy and 3-4 times that of steel.

Wires, connectors, household appliances, electronic components, radiators, tableware, etc.

Reflection performance

Aluminum alloy has good reflection properties for light, heat radiation and electric waves. After surface polishing or electrolytic polishing, this function can be greatly enhanced.

Reflectors, lighting accessories, refrigerator enclosures, electric heater accessories, etc.

Non-magnetic

Aluminum alloy is a non-magnetic material。

Instrument accessories, antennas, compasses used on ships, radar accessories, and other anti-interference custom parts.

Low temperature resistance

Aluminum alloy is a metal material that is very suitable for operation in a low temperature environment. Low temperature will increase the strength of the aluminum alloy without increasing the brittleness of the material.

Spare parts required for operation in low temperature environment.

Surface treatment of aluminum fabrication parts

Supro MFG will choose the right materials, accessories, manufacturing process, etc. according to your needs and application. At the beginning of custom aluminum fabricated projects, all fabrication details will get your permission. Helping you to complete your project with the easiest and most efficient way.

Powder Coating

Effectively wraps metal surfaces and resists rust with aesthetically pleasing custom colors.

anodic oxidation

Forms an oxide film on the surface of aluminum alloy to improve hardness, aesthetics, and corrosion resistance.

Brushed polished

It presents a glossy metallic texture with an even grain that enhances the aesthetics of the product.

sandblast

Cleaning the metal surface, presenting a uniform roughness and improving the adhesion of the paint.

mirror polishing

The metal surface is polished and honed to give a mirror-like finish, increasing the aesthetic effect of the part.

electroplated

A metal protective film, improve wear resistance, conductivity, reflectivity, corrosion resistance and enhance the role of aesthetic.

laser engraving

Commonly used for engraving on the surface of parts, logos, product descriptions, or complex patterns.

screen printing

Printing paint onto the surface of a product creates content of any shape and color that is hard-wearing and beautiful.

No design files? Let Supro MFG do it for you.

We often come across clients who have no professional design drawings and documentation, only a creative idea, which leads to the project being at a standstill.

If you are in this situation, then contact our team of experts.

Supro MFG, as an industry-leading custom aluminum fabricator, has an ever-experienced team of engineers who utilize their extensive fabrication experience and technical expertise to build your idea into a real product and create design files such as STEP/STP/SLDPRT/DXF/PDF/PRT/DWG/AI.

That’s what makes SUPRO MFG so great, and 2,000 corporate, entrepreneurial, artist, and other purchasers from around the world enjoy working with us and benefiting from our one-stop manufacturing services.

F.A.Q

Supro MFG is a professional Chinese sheet metal manufacturer, we specialize in the design and manufacture of custom sheet metal parts fabrication and Sheet metal Prototype, ISO 9001-2015 certified, providing a full range of sheet metal parts fabrication solutions and technical support .

We are not a trader, all products are done in our in-house factory, we have a reliable supplier of surface treatment, heat treatment, and standard parts to support us, and we can provide you with economical sheet metal manufacturers ex-works prices.

We have our own sheet metal fabrication factory, welding workshop, laser cutting workshop, and precision CNC Machining workshop, with a total area of more than 3000 square meters, with 12 technical engineers, 36 skilled workers, 6 quality engineers, and a professional English sales team.

Of course, we keep all the customer's information confidential, sign a non-disclosure agreement, our factory will not allow unrelated personnel to enter without authorization, your product design and patented technology will be protected by us.

Yes, we have rich manufacturing experience and technical knowledge, can draw professional design files (including: STL/STEP/IGES/PDF/CAD, etc.) according to your ideas, and provide you with free manufacturability solutions. Actively help you optimize product design, reduce costs, and make your product design more dynamic in the sales market.

From raw materials to finished packaging, we will provide you with reliable quality inspection reports and photos at any time. If you need an authoritative third-party inspection report, we can also actively cooperate to ensure that you will receive high-quality products.

T/T, Paypal western union, L/C, and other channels you suggest (contact us for negotiation).

Yes, we can provide system documentation for PPAP level3.

Our quotations are all factory quotations from manufacturers, and all manufacturing costs and labor costs are traceable. We all use the raw materials of authoritative manufacturer brands, refuse to cut corners, and all products are subject to our quality control.

While there are plenty of small businesses that offer you a very low price, the quality can be at risk.

What your project needs more is the guarantee of high-quality products and on-time delivery, not high-risk.

We do not set a minimum order quantity. Whether you need a small amount of prototypes or large quantities, we will treat you equally and provide you with a full range of manufacturing services and technical support.

We will develop a detailed production plan, every point in time will be practically verified, and all processes are under our monitoring to ensure on-time delivery of high-quality products. (Except for the influence of force majeure factors)

Once there is a signal of delay, we will organize more production capacity to ensure on-time delivery.

online custom aluminum fabrication Quote services

Only 4 steps

Contact our experts team and experience the efficiency and economic benefits of digital metal fabrication services.

Upload Design Files

STL , STEP (.stp), IGES (.igs), (.ZIP), or PDF.

Also be a sample or an idea

Quote & Design Analysis

Instant factory quotes and DfM reports, the most reasonable solution.

Manufacturing Begins

Digital processes can initiate order tasks within 24 hours.

On-Time Delivery

Keeping delivery promises, approved by 3000+ Global Company buyers.

BLOG

Looking for a reliable and economically competitive aluminum fabricator?

Please contact our expert team to quickly start your next custom aluminum alloy parts project.

And benefit from it.